sdew99

CB750 Enthusiast

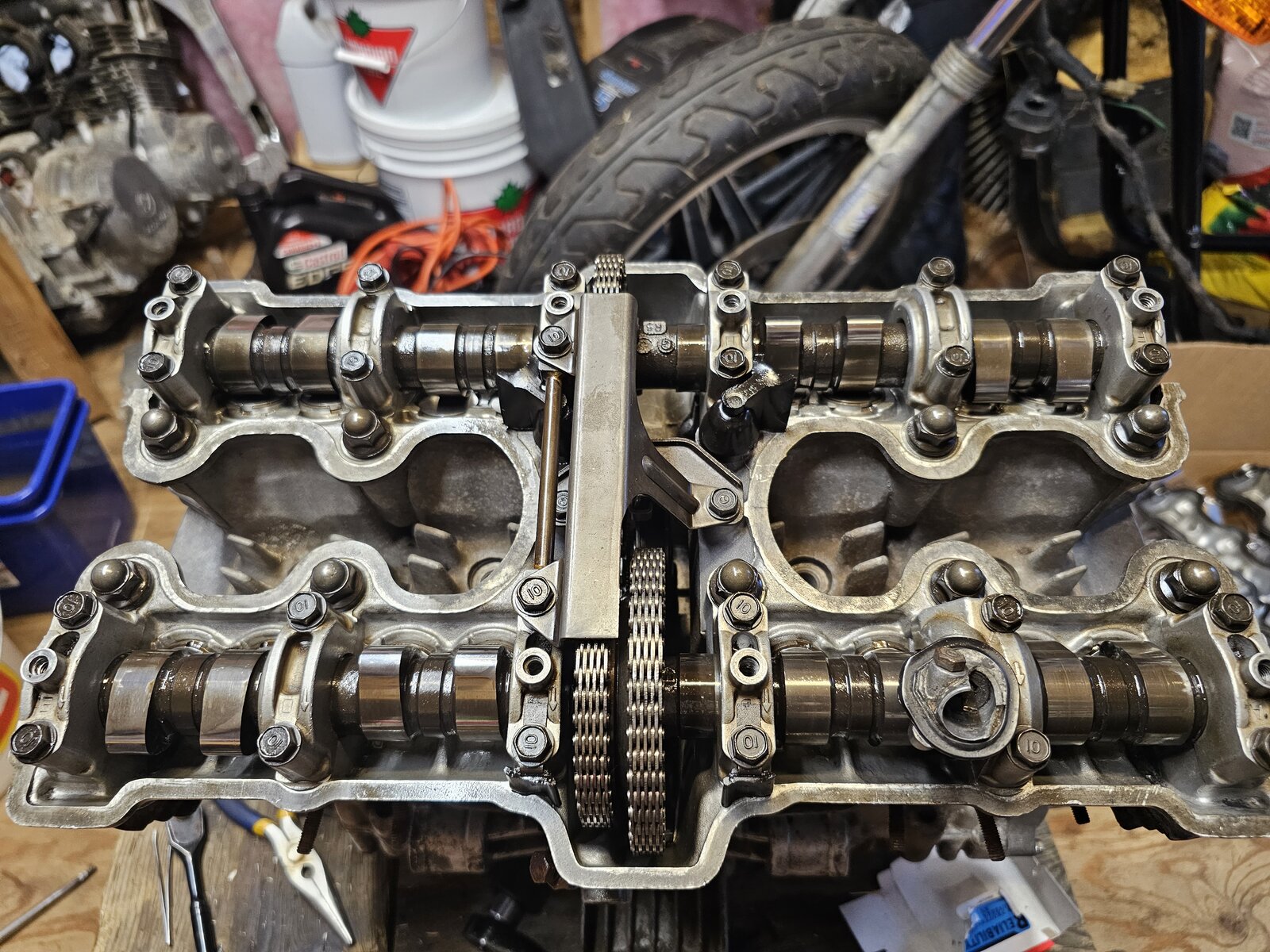

Hi all, I have a 1979 cb750k that I am rebuilding and have run into a roadblock.

I disassembled the head and cylinder due to low compression so piston rings were replaced, new cylinder gasket, new cylinder head gasket, etc.

After reassembling, I performed a compression test and was between 50-90. I then realized that my exhaust cam was slightly out of time, so I went back and removed the cams, and made sure they were in time (level with cylinder head at the TDC mark and cylinder one lobes pointing towards spark plugs).

Performed another compression to have the exact same results as before. Did a wet test, and the compression rose to 120-150 across the board.

Dreading the thought of removing the head and cylinders again to inspect the rings... rings were staggered and seemed to fit into grooves without any issues so hard for me to believe they are the issue but all things are pointing that way.

Wondering if anyone has any insight to other causes that could be contributing to low compression.

Thanks!

I disassembled the head and cylinder due to low compression so piston rings were replaced, new cylinder gasket, new cylinder head gasket, etc.

After reassembling, I performed a compression test and was between 50-90. I then realized that my exhaust cam was slightly out of time, so I went back and removed the cams, and made sure they were in time (level with cylinder head at the TDC mark and cylinder one lobes pointing towards spark plugs).

Performed another compression to have the exact same results as before. Did a wet test, and the compression rose to 120-150 across the board.

Dreading the thought of removing the head and cylinders again to inspect the rings... rings were staggered and seemed to fit into grooves without any issues so hard for me to believe they are the issue but all things are pointing that way.

Wondering if anyone has any insight to other causes that could be contributing to low compression.

Thanks!