bradenhall

CB750 New member

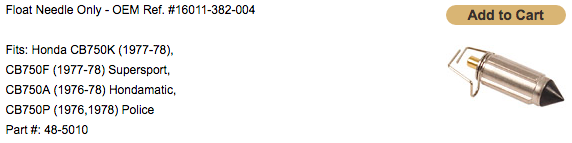

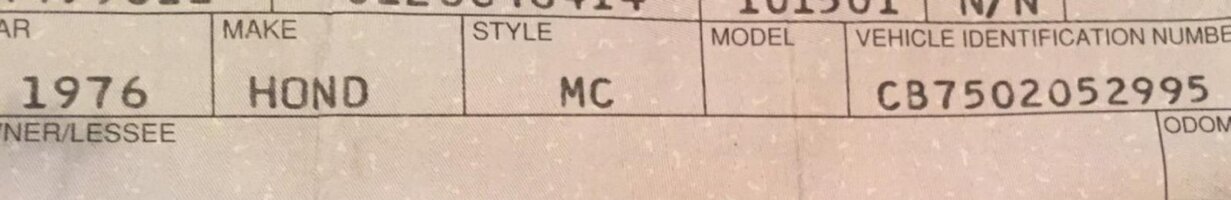

First post here, I recently purchased a 76 cb750K and i'm having issues getting the float valve needles to seat, which is resulting in overflow on one or more of the carbs. The valve needles are different than the stock ones in the manual, with a black rubber tip and a clips that hold them to the floats (just like these shown below)

The stock 76 valve needles are all metal, with no clips attached to the floats like the ones shown below.

I've adjusted the floats several times, but I keep getting the same problem. I'm wondering if these valve needles are the wrong ones for this year, and if i need to replace them, or if I just need to adjust to floats more.

Sorry if this was already posted in anothr thread, I wasn't able to find anything answering this question. Thanks

The stock 76 valve needles are all metal, with no clips attached to the floats like the ones shown below.

I've adjusted the floats several times, but I keep getting the same problem. I'm wondering if these valve needles are the wrong ones for this year, and if i need to replace them, or if I just need to adjust to floats more.

Sorry if this was already posted in anothr thread, I wasn't able to find anything answering this question. Thanks