chrome72

CB750 Member

First time poster and learning a ton.

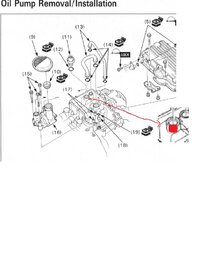

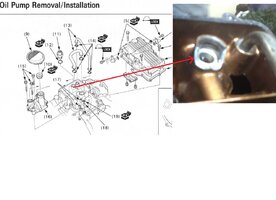

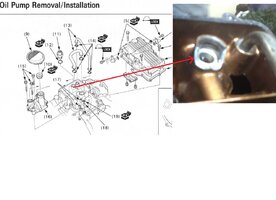

Recently purchased a 1992 Honda Nighthawk 750 which was in pieces. Attempted to get motor in the bike frame but it got stuck at a weird angle. Ended up having to take off the housing cap where the oil pump resides to get engine out. I ended up breaking a piece/tube that holds the pressure relief valve in the process.

I took the service manual page that shows what I am talking about and a picture of the aftermath.

Did I totally just destroy the engine? Or is the actual housing cap (aka the very bottom of the engine) and the remaining piece that holds the relief valve enough to have a working engine?

Appreciate any advice,

Recently purchased a 1992 Honda Nighthawk 750 which was in pieces. Attempted to get motor in the bike frame but it got stuck at a weird angle. Ended up having to take off the housing cap where the oil pump resides to get engine out. I ended up breaking a piece/tube that holds the pressure relief valve in the process.

I took the service manual page that shows what I am talking about and a picture of the aftermath.

Did I totally just destroy the engine? Or is the actual housing cap (aka the very bottom of the engine) and the remaining piece that holds the relief valve enough to have a working engine?

Appreciate any advice,