jimminy

CB750 Enthusiast

OK, now I get it. Maybe the next time I brave one of these projects I'll do the adjustable sprocket. For this one, I'm going to just do the best I can with what I have.

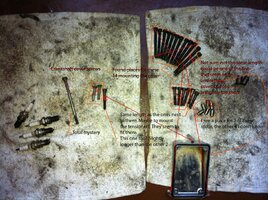

So, it was a bad day today. While looking at this valve adjustment thing I noticed something I can't even explain. See the photos below

![IMG_0997[1].jpg IMG_0997[1].jpg](https://www.cb750.com/data/attachments/1/1362-c819874199a67e6c2888e666ef7e1bce.jpg)

![IMG_0998[1].jpg IMG_0998[1].jpg](https://www.cb750.com/data/attachments/1/1363-110b33367839bf13020f6facbf29f319.jpg)

When I installed the cam chain I would have sworn on my life that I had this all aligned perfectly. Somehow today I see that when things are aligned correct at the drive shaft, I'm 90 degrees wrong on the cam. I assume I'll just have to take the cam sprocket off again and rotate everything. Does this mean I need to take the cam all apart again or can I just remove the cam sprocket bolts, remove the chain and rotate things into place?

That's bad. But what's worse is I think I just felt some aluminum threads go out. I was using a torque wrench that was probably too big (but still should have worked) on the bolts to attach the cam holder and it just went mushy. So that's probably toast. I just ordered a smaller torque wrench from Harbor Freight that supposed to go down to 5 ft-lbs. I guess I'll see if I can torque it the 9 ft-lbs the manual wants and if I can't have to come up with an inexpensive repair. Lovely.

So, it was a bad day today. While looking at this valve adjustment thing I noticed something I can't even explain. See the photos below

![IMG_0997[1].jpg IMG_0997[1].jpg](https://www.cb750.com/data/attachments/1/1362-c819874199a67e6c2888e666ef7e1bce.jpg)

![IMG_0998[1].jpg IMG_0998[1].jpg](https://www.cb750.com/data/attachments/1/1363-110b33367839bf13020f6facbf29f319.jpg)

When I installed the cam chain I would have sworn on my life that I had this all aligned perfectly. Somehow today I see that when things are aligned correct at the drive shaft, I'm 90 degrees wrong on the cam. I assume I'll just have to take the cam sprocket off again and rotate everything. Does this mean I need to take the cam all apart again or can I just remove the cam sprocket bolts, remove the chain and rotate things into place?

That's bad. But what's worse is I think I just felt some aluminum threads go out. I was using a torque wrench that was probably too big (but still should have worked) on the bolts to attach the cam holder and it just went mushy. So that's probably toast. I just ordered a smaller torque wrench from Harbor Freight that supposed to go down to 5 ft-lbs. I guess I'll see if I can torque it the 9 ft-lbs the manual wants and if I can't have to come up with an inexpensive repair. Lovely.

![IMG_1014[1].jpg IMG_1014[1].jpg](https://www.cb750.com/data/attachments/1/1391-044c32d913c54b9f0caa1b560279d88e.jpg)

![IMG_0999[1].jpg](/data/attachments/1/1389-cc99c645b4a60722ba1c0dac640918ef.jpg)