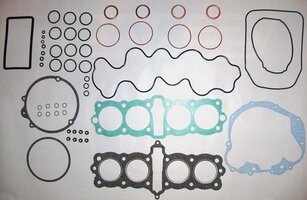

small red orings are for the oil gallery between the cylinder and head(around the two rear centermost cylinder studs)

8 big black orings are for the tappet covers

8 seals are valve stem seals

8 black rubber tubes are for later model cylinders with the thin metal sleaves. The are a seal for the oil return galleries. If your cylinder has very thing metal sleeves in some of the cylinder stud holes you use these if there are no metal sleeves you dont use them.

4 big red orings go around the bottom of the cylinders where the sleeve meats the block...the originals are more than likely black and are really stuck in there but if they are hard and brittle they should be replaced. Dig them out with a pick.

The 5 small black orings may be for between the head and the cam towers but you only need 4, not sure why there are 5 of the same size. The 5th one may be for the left side transmission bearing retainer oil gallery. Kind of hard to determine dimensions and thickness of the orings.

Thanks for the reply DD!

-The tappet cover-check

-The valve stem seals-check, Found these in the manual's diagram finally, but I'm not doing the valves so I guess I don't need these

-Oil return gallery seals-I have a package the guys who took the top end apart gave me that says "valve guide B250 X2". There are 4 thin metal tubes, one longer than the others 3. One of them has one of these rings around it, another has 2, the long one and one of the short ones has none. I'm lost on this one, not sure where they go and can't find anything in the manual.

-Red O-rings-check, I think. Where the jugs come out of the cylinder block where it'll touch the crank-case, there's a gap. The cylinder block was totally cleaned up at the machine shop so no residue to go by, but looks like a good place for an O-ring to seat in.

-5 Small black rings-Check. I don't know why there's 5 either, the package says there should be 4. These are the only ones I felt like I knew where to go with them.

Thanks again, I get the feeling you could put one of these together in your sleep.

BTW, I did a new cam chain today by removing a link in a new chain and replacing with a master link. I got it in alright but didn't have a good tool for this. After some work getting the pins through and the links tight I have it together as good as any of the others except that all the other pins seem to be kind of notched in such a way as they will never come out. I don't have any way to do this, but the thing is in so tight I can't imagine it ever popping out on it's own. Is there any reason to worry it might after some miles?

Sorry, one more question. I have a head gasket from cycle-X that's supposed to be the best since forever according to cycle-X. The rest are regular gaskets that came with a top-end rebuild kit. Do I need to prep any of those gaskets in some way? Online everyone seems to have their own opinion about it. Copper spray, gasket sealer, etc. Any advice?

Ok, done.

Best,JD

![IMG_0987[1].jpg IMG_0987[1].jpg](https://www.cb750.com/data/attachments/1/1357-db3a991448aa378e3716b75c797290e0.jpg)