Wez_

CB750 Addict

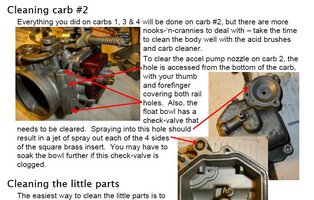

You should see all the ninja hooks I've created to try and snake this nozzle. On the number 1 carb, the nozzle is plugged. Can i drill out the small brass ball underneath the nozzle on the base of the carb to grant access to the nozzle? Seems like the only way to access this thing. I've heated the nozzle with a torch and watched boiling solvent do nothing. The nozzle tip is cleared along with the rail hole. The clog is somewhere inside. Would CLR be ok to use?

If I drilled out that Brass plug, then will it grant access to the nozzle? I could then have the hole welded shut with aluminum? idk

If I drilled out that Brass plug, then will it grant access to the nozzle? I could then have the hole welded shut with aluminum? idk

Last edited: