Hello people!

I need your help.

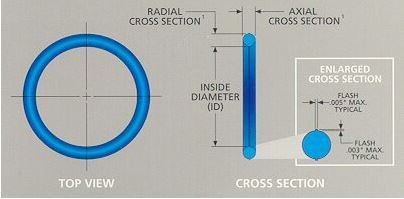

I've seen this O-ring between the engine body, and when I took it out, it broke by itself (30 years old).

The problem is that I can not find the part, to be able to change it.

It doesn't appear in the diagrams of the web pages of purchase.

For example:

https://www.cmsnl.com/honda-cb750f2-1982-c-general-export-kph_model14880/partslist/E13.html#results

Anyone know where to find this O-ring?

This is the upper side

Thanks in advance!

Tronco

I need your help.

I've seen this O-ring between the engine body, and when I took it out, it broke by itself (30 years old).

The problem is that I can not find the part, to be able to change it.

It doesn't appear in the diagrams of the web pages of purchase.

For example:

https://www.cmsnl.com/honda-cb750f2-1982-c-general-export-kph_model14880/partslist/E13.html#results

Anyone know where to find this O-ring?

This is the upper side

Thanks in advance!

Tronco