So, here's the situation. 1976 K model is stock as far as I know. Ran fine for the past year. No issues with accelerating or starting. Did a tune up, replaced plugs, points, condensers, and oil/filter. Timing is nuts on, checked with a light. Gaps are correct on points. Went out to ride and the bike hesitates from a stop. It runs rougher than before and smells rich. Pull choke when warmed up and bike wants to die. Got about 40mi less from a tank of gas too. Runs, idles fine if I brap the throttle it misses then catches up.

-

Enter the April CB750 Supply gift certificate giveaway! It's easy... Click here, post something, and you're entered into the drawing!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Check compression to verify first then put old condensers back in and see how it runs. Cheap aftermarket points and condensers are junk and cause more issue then anything. You need to start from the beginning and verify everything. If all you did was change the tune up parts then start by putting back the old stuff one thing at a time till you find what is causing your issue. You will need to replace the fouled plug as it will never clean up and can continue to give you issues. Make sure advancer works and isnt stuck or something happened while changing points. If it ran good before your tuneup then your tune up procedure or the parts are an issue.

amc49

CB750 Guru

X2. We get people all the time saying 'it's all dead on'. if it ran pretty good before then it screams the quality of parts or the work, no other way around it. If setting point gaps without using a dwell meter then you have literally NO WAY to tell if the gap is right or not.

Since the #1 plug fouled look at the 1-4 side on the ignition.

Since the #1 plug fouled look at the 1-4 side on the ignition.

Ok, well #4 is fine and #1 is fouled, so if I jacked up the ignition, which a Honda certified tech was helping me with, why would only 1 cylinder be affected? The line is directly under the F mark on all cylinders during the timing gun check. That's pretty dead on as far as I can tell. I appreciate the help but gaps are gaps and timing is timing. It's either in or it's out and I can tell you it is definitely in.

amc49

CB750 Guru

There can be way more than one reason why a plug fouls before another. The tech should easily know that.

Of course you could always have had something else go wrong there, past that, to not suspect your own work is death. You are the one saying it ran fine before the tuneup...........

Of course you could always have had something else go wrong there, past that, to not suspect your own work is death. You are the one saying it ran fine before the tuneup...........

Dwell must be checked! Point gap is kind of just a starting point, dwell is more important, if point gap is on but dwell is way off you have worn point cam. Many modern techs have no idea how to actually work on point systems. If a person has never worked on the old honda point systems it is easy to not get it right...even slightly off affects the performance big time. AS said, if it ran good before the tune up and runs bad now, something done during the tuneup is wrong. Did you turn the motor over with the nut on the point side of the motor? If so you very easily could have tweeked the assembly, Its a no no to turn it over by hand on the point side, very easy to introduce runout into the advancer assembly, then causing erratic timing. All we can do is tell you what we see from the outside looking in. Start from the beginning, check basics and check engine condition, the check parts you have installed and swap out as necessary. You never specified what you used for parts and if you checked engine condition. New parts mean new they dont mean they are good, aftermarket point parts are normally junk you need to go with genuine honda.

So, timing is on. Gaps at widest point are on. Points start to open at the F mark. Didn't mess with the cam so I am not sure how it could be fine before the tune up but worn so bad only one cylinder is running rich now. I'll try dwell next. That seems Tonne to be the only thing that we didn't set per a meter or anything. I am trying not to be a dick to the dude that helped me out. He works on older bikes at the shop but I am sure since they are few and far between he's not perfect. He's younger than me so there's that. I'll try dwell. Or electronic ignition. Lol

Dave

CB750 Junkie

Ok, well #4 is fine and #1 is fouled, so if I jacked up the ignition, which a Honda certified tech was helping me with, why would only 1 cylinder be affected? The line is directly under the F mark on all cylinders during the timing gun check. That's pretty dead on as far as I can tell. I appreciate the help but gaps are gaps and timing is timing. It's either in or it's out and I can tell you it is definitely in.

Maybe, the #1 plug wire cracked open when it was moved to replace the plugs or the connection to the plug cap is now loose. PS The plug caps can go bad too. They are not just connectors, they have a specific resistance.

You pop off the cover on the other side of the motor and turn it from that side.How do you advance it then without turning the big advancing nut?

Crap parts are the usual suspect. Like the others said, the aftermarket condensers are usually garbage and oem ones are insanely expensive. Look at the points with a magnifying glass, are the contacts properly lined up, are they parallel?

If it ran fine, why did you get a tune up? (If it works, don't fix it)

Electronic is the way to go. Get a pamco, a new set of coils, and a new set of plug caps, and you'll never regret it.

amc49

CB750 Guru

FYI. the point gap from around .012"-.016", better to be closer as long as the points don't arc any more. The closer setting maximizes coil saturation time, which increases spark intensity. The condensers are what are supposed to stop most of that arcing and how they become a problem.

Wouldn't hurt to pop that #1 carb fuel bowl and check for like a loosened main jet or such, it's not impossible.

I myself use car smallblock Chevy condensers mounted up under the tank at the coils, they work fine.

Like said, you use the alt rotor bolt on opposite side to turn the engine, a pain considering you are looking at the opposite side.

Wouldn't hurt to pop that #1 carb fuel bowl and check for like a loosened main jet or such, it's not impossible.

I myself use car smallblock Chevy condensers mounted up under the tank at the coils, they work fine.

Like said, you use the alt rotor bolt on opposite side to turn the engine, a pain considering you are looking at the opposite side.

That is a pain and also not what the clymers says. I am confused how turning the nut that looks as if it was engineered specifically for that purpose does any harm. Also, pulling the rotor cover means pulling the shift cover and replacing the gaskets as well as the oil that will now dump out of the case.

Checked the plug and there's a nice, fat spark when it cranks. So there is spark, definitely have fuel and the gaps were set within range and timing is in with the strobe. So far I need to figure out how I check dwell and check the carb.

Dave

CB750 Junkie

That is a pain and also not what the clymers says. I am confused how turning the nut that looks as if it was engineered specifically for that purpose does any harm. Also, pulling the rotor cover means pulling the shift cover and replacing the gaskets as well as the oil that will now dump out of the case.

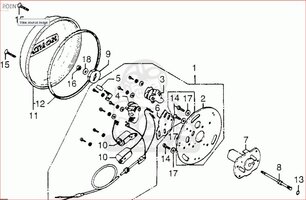

That's not a nut, (#9) it's a special washer for the tiny nut (#16) in the middle of it. Look at that tiny nut in the middle and the tiny (advancer) shaft (#8) it is it threaded onto. That tiny shaft is what your putting enough force to turn over the engine on.

The alternator cover is separate from the shifter cover and though it has a paper gasket to keep out the dirt the only oil it may have in it would be that which leaked out of the crankshaft seal, which is located behind the alternator rotor on that side.

Last edited:

Have you ever pulled that cover? It is seperate, however, the wires run from the magneto under the shifter cover to the harness. It is impossible to disconnect the wires to move the magneto cover without removing both covers. Also, I always get about a half a quart of oil at least from the case. Furthermore, the "force required to turn the entire engine" A. is not that much force, and B. is even less force when you pull the plugs. This isn't a thread about how to crank the engine, I just wanted to know if the symptoms above pointed to anything in particular that could be glaringly wrong. Thanks for the help on that question to those who have answered.

On a seperate note, a small puddle of fuel was under the bike. I left the fuel on accidentally. Now I'm thinking float may be bad. That's next to check.

On a seperate note, a small puddle of fuel was under the bike. I left the fuel on accidentally. Now I'm thinking float may be bad. That's next to check.

Dave

CB750 Junkie

If you go back to post #7 by dirt digger..

Then in your own reply, #13, you said

If your turning the engine over using that nut shaped washer, you may have already bent the advancer shaft. If you have, you'll never get the timing right.

Did you turn the motor over with the nut on the point side of the motor? If so you very easily could have tweeked the assembly, Its a no no to turn it over by hand on the point side, very easy to introduce runout into the advancer assembly, then causing erratic timing.

Then in your own reply, #13, you said

I am confused how turning the nut that looks as if it was engineered specifically for that purpose does any harm.

If your turning the engine over using that nut shaped washer, you may have already bent the advancer shaft. If you have, you'll never get the timing right.

https://m.youtube.com/watch?v=VoNhm2Tq7lM

One of about a hundred videos online of doing exactly what you say is not to be done. The timing marks are on that side for a reason...

One of about a hundred videos online of doing exactly what you say is not to be done. The timing marks are on that side for a reason...

Get it close with the starter then you can use the kick starter or put it in gear up on the center stand and turn the back tire. One you get it very close you can use a socket on the nut on the point side but dont put any side pressure only rotational force. And just because the clymer manual says you can do it or because the hacks on youtube do it definitely doesnt mean you should. If you are dead set on turning it with that nut go for it, its your bike and now your problem to deal with it. I have seen out of round point breaker cams many times because the previous person put a cresent wrench on the nut and turned it over, have also seen the thing broke off or at the very least damaged.

Alt cover can be removed by itself, there is just enough play you dont even have to unhook the wires, but all you gotta do is pop the starter cover off and you can usually move the wires to get some extra slack. Just saying from experience.

As said several times in previous posts....check the basics, that also means float level, lose jets etc as mentioned before. Only so much we can do for you over the internet and can only give you so much advice from previous experience, we have given many things to check. Whether you choose to listen to us or listen to youtube is up to you. I am done, good luck hope you get it figured out.

Alt cover can be removed by itself, there is just enough play you dont even have to unhook the wires, but all you gotta do is pop the starter cover off and you can usually move the wires to get some extra slack. Just saying from experience.

As said several times in previous posts....check the basics, that also means float level, lose jets etc as mentioned before. Only so much we can do for you over the internet and can only give you so much advice from previous experience, we have given many things to check. Whether you choose to listen to us or listen to youtube is up to you. I am done, good luck hope you get it figured out.

amc49

CB750 Guru

While the bigger 'washer nut ' was put there to turn engine with, it often makes problems doing it, both the part 8 and 9 there are simple non-hardened cheap steel and easily damage. The 6mm. nut there is not strong enough to really hold all that in place and timing CAN move sometimes. I've seen it happen on 550 which uses the same parts and setup there. X2 post #19.

You can under certain circumstances have wonderful spark out in the open and then it shorts down side of plug under compression pressure, and very possible if the porcelain on plug is black. Gauging spark intensity by eyesight alone is always highly suspect and often Merlin witchery. It is empirical evidence at best and often wrong. I say that after seeing 'superhot' spark on so many engines I cannot count, they later proved to have ignition issues. It by itself means nothing, added to other tests it can be of value.

All youtube shows is that a hundred people can easily be wrong about things. Nothing new there. I watch lots of stuff there but maybe 10% of it I value and most of the people doing the how-tos have not a clue. I watch to see things NOT to do and to see what parts look like inside things to learn instantly why I often would NOT be doing things exactly like they show.

Clymer? Please don't. So many mistakes and omissions in them it's funny. Haynes too. Even the OEM Honda service manuals have some mistakes in them.

If they run ethanol laced fuel in your local gasoline then it could easily be that, look for fine red rust in the fuel bowl. Practically no filter on the planet catches all of that and then it makes the float not seat correctly over and over to drive you nuts. It's a major problem on older bikes and the more they sit the worse it gets. Ethanol is transparent in use if the vehicle driven every single day, it's letting them sit that kills you while using it. I've had stuck floats in less than a week of sitting.

You can under certain circumstances have wonderful spark out in the open and then it shorts down side of plug under compression pressure, and very possible if the porcelain on plug is black. Gauging spark intensity by eyesight alone is always highly suspect and often Merlin witchery. It is empirical evidence at best and often wrong. I say that after seeing 'superhot' spark on so many engines I cannot count, they later proved to have ignition issues. It by itself means nothing, added to other tests it can be of value.

All youtube shows is that a hundred people can easily be wrong about things. Nothing new there. I watch lots of stuff there but maybe 10% of it I value and most of the people doing the how-tos have not a clue. I watch to see things NOT to do and to see what parts look like inside things to learn instantly why I often would NOT be doing things exactly like they show.

Clymer? Please don't. So many mistakes and omissions in them it's funny. Haynes too. Even the OEM Honda service manuals have some mistakes in them.

If they run ethanol laced fuel in your local gasoline then it could easily be that, look for fine red rust in the fuel bowl. Practically no filter on the planet catches all of that and then it makes the float not seat correctly over and over to drive you nuts. It's a major problem on older bikes and the more they sit the worse it gets. Ethanol is transparent in use if the vehicle driven every single day, it's letting them sit that kills you while using it. I've had stuck floats in less than a week of sitting.

Last edited:

Similar Threads

- Replies

- 18

- Views

- 239

- Replies

- 11

- Views

- 1K

- Replies

- 33

- Views

- 4K

- Replies

- 7

- Views

- 1K